Press Release

COMSOL Helps Leading Energy Technology Company Save 30% in Prototyping Costs

Ultrasonic simulations enable Baker Hughes to study acoustic wave propagation, which helps in the optimization of transducers used for testing extracted oil and gas.

BURLINGTON, MA (September 9, 2025) — In the oil & gas industry, assessing the quality of gas as it is extracted is a critical step to ensure the product meets quality standards before continuing with the rest of the refinement process. In order to do so, Baker Hughes, an energy technology company, relies on pulse-echo and pitch-catch testing, which incorporates ultrasonic transducers to identify impurities. To improve its transducer design, Baker Hughes turned to COMSOL, a global leader in modeling and simulation software.

"Overall, simulations have been saving us about 30% on prototyping costs," said Haiqi Wen, a lead scientist at Baker Hughes. "In the past, when we needed to order new transducers, we would usually order a batch of different transducers with different specs. But now that we have been using simulation software like COMSOL Multiphysics®, we just need to verify that there are a few good designs in the batch. Then, we just need to order those designs instead of ordering all of the new transducer designs and testing which one performs the best."

Modeling piezoelectric transducers with the COMSOL Multiphysics® software enabled the team to couple fluid to the transducers, elastic waves to pressure acoustics, and an external electrical circuit to the terminal of the piezoelectric element. These couplings made it possible to accurately examine how multiple physics phenomena interact and model the transformation of voltage signals to elastic waves as well as fluid–structure interaction at the transducer's boundary with customized circuit parameters.

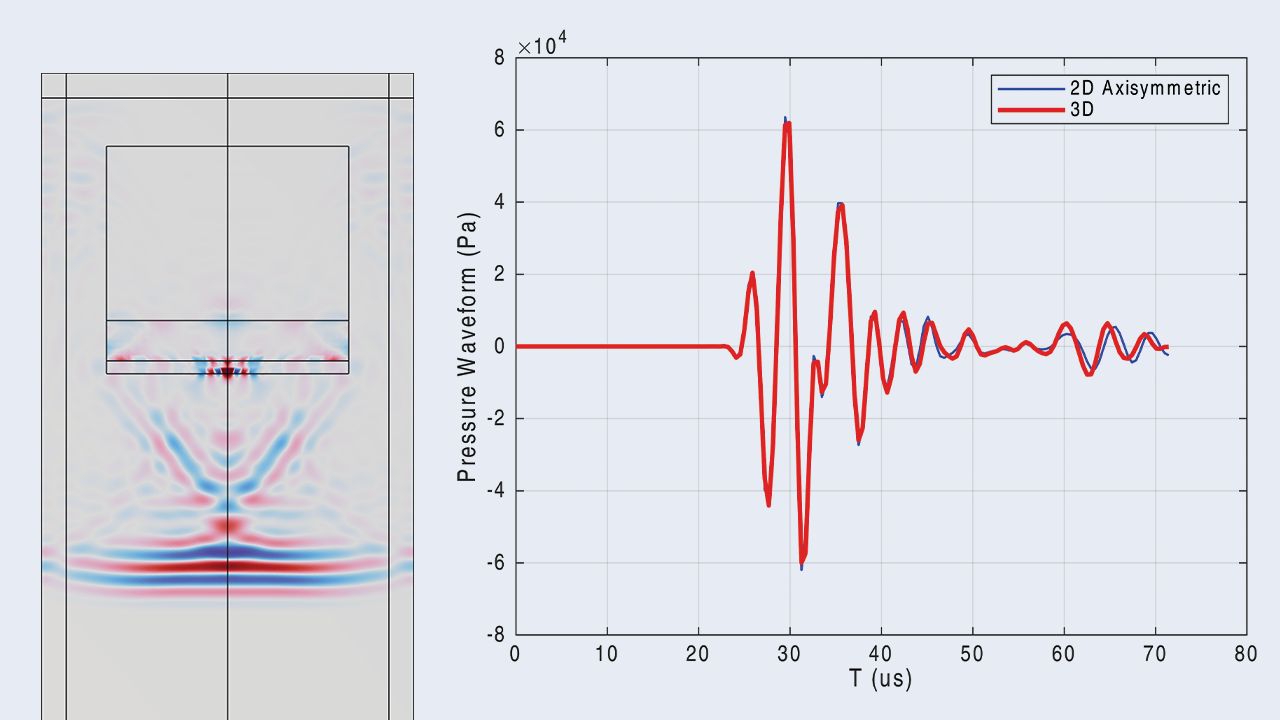

The team built a simplified, axisymmetric 2D transducer model as well as a full 3D model and validated both models against experimental testing. The simulation sends out a brief pulse signal that strikes the cement surface of the well. The wave propagation was nearly identical in the two models, and there was good agreement between the pressure probe responses.

The 3D transducer model with a pulse signal (left) and the graph results that show good agreement between the pressure probe responses of the 2D and 3D models (right).

Furthering their work, Wen and his team used COMSOL Multiphysics to simulate and optimize pulse-echo and pitch-catch testing. Their pulse-echo simulation highlights an ultrasonic nondestructive testing (NDT) technique that sends out ultrasonic pulse waves to identify defects in materials or analyze the reflective waveforms for information. Simulating the two testing methods in COMSOL Multiphysics allows for increased efficiency in gathering data from the ultrasonic pulse waves, and modeling the transducer conserves resources while optimizing the design.

About COMSOL COMSOL is a global provider of simulation software for product design and research to technical enterprises, research labs, and universities. Its COMSOL Multiphysics® product is an integrated software environment for creating physics-based models and simulation apps. A particular strength is its ability to account for coupled or multiphysics phenomena. Add-on products expand the simulation platform for electromagnetics, structural, acoustics, fluid flow, heat transfer, and chemical applications. Interfacing tools enable the integration of COMSOL Multiphysics® simulations with all major technical computing and CAD tools on the CAE market. Simulation experts rely on COMSOL Compiler™ and COMSOL Server™ to deploy applications to their design teams, manufacturing departments, test laboratories, and customers throughout the world. Founded in 1986, COMSOL has 16 offices worldwide and extends its reach with a network of distributors.

COMSOL, COMSOL Multiphysics, COMSOL Compiler, and COMSOL Server are either registered trademarks or trademarks of COMSOL AB.

COMSOL, Inc.

100 District Avenue

Burlington, MA 01803

USA

Phone: +1-781-273-3322

View on a map

Editor Contact:

Mike Nourie

michael.nourie@comsol.com